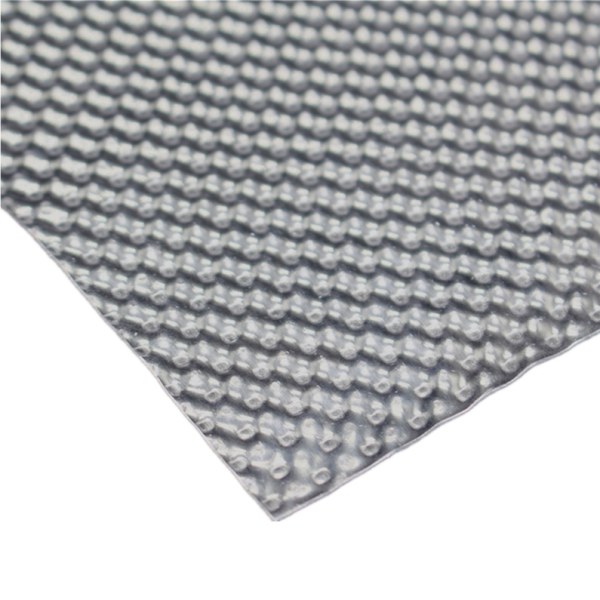

M·ªòT t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒê√¢y l√Ý m·ªôt b·ªô ph·∫≠n qu·∫£n l√Ω nhi·ªát ƒë∆∞·ª£c s·∫£n xu·∫•t t·ª´ t·∫•m nh√¥m ƒë∆∞·ª£c √©p c∆° h·ªçc th√Ýnh c√°c hoa vƒÉn n·ªïi. C√°c hoa vƒÉn n√Ýy ƒë∆∞·ª£c thi·∫øt k·∫ø ƒë·ªÉ tƒÉng c∆∞·ªùng hi·ªáu su·∫•t nhi·ªát, ƒë·ªô ·ªïn ƒë·ªãnh c·∫•u tr√∫c v√Ý kh·∫£ nƒÉng ki·ªÉm so√°t lu·ªìng kh√¥ng kh√≠ trong m√¥i tr∆∞·ªùng nhi·ªát ƒë·ªô cao.

Kh√°c v·ªõi c√°c t·∫•m nh√¥m tr∆°n nh·∫µn, b·ªÅ m·∫∑t d·∫≠p n·ªïi t·∫°o ra h√¨nh d·∫°ng h√¨nh h·ªçc ƒë∆∞·ª£c ki·ªÉm so√°t trong v·∫≠t li·ªáu. H√¨nh d·∫°ng h√¨nh h·ªçc n√Ýy l√Ým tƒÉng ƒë·ªô c·ª©ng v√Ý t·∫°o ra c√°c t√∫i kh√≠ si√™u nh·ªè gi√∫p gi·∫£m truy·ªÅn nhi·ªát. Do ƒë√≥, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒë∆∞·ª£c s·ª≠ d·ª•ng r·ªông r√£i ·ªü nh·ªØng n∆°i c·∫ßn gi·∫£m tr·ªçng l∆∞·ª£ng, ph·∫£n x·∫° nhi·ªát v√Ý ƒë·ªô b·ªÅn cao.

T·ª´ h·ªá th·ªëng ·ªëng x·∫£ ƒë·∫øn c√°c thi·∫øt b·ªã c√¥ng nghi·ªáp, c√°c gi·∫£i ph√°p t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒë∆∞·ª£c thi·∫øt k·∫ø ƒë·ªÉ c√¢n b·∫±ng gi·ªØa hi·ªáu su·∫•t, chi ph√≠ v√Ý ƒë·ªô tin c·∫≠y l√¢u d√Ýi.

C√°c hoa vƒÉn d·∫≠p n·ªïi gi√∫p ph√¢n t√°n nhi·ªát b·ª©c x·∫° v√Ý h·∫°n ch·∫ø d·∫´n nhi·ªát tr·ª±c ti·∫øp. K·∫øt qu·∫£ l√Ý kh·∫£ nƒÉng ph·∫£n x·∫° nhi·ªát ƒë∆∞·ª£c c·∫£i thi·ªán v√Ý nhi·ªát ƒë·ªô b·ªÅ m·∫∑t th·∫•p h∆°n tr√™n c√°c b·ªô ph·∫≠n ƒë∆∞·ª£c b·∫£o v·ªá.

D·∫≠p n·ªïi gi√∫p tƒÉng c∆∞·ªùng ƒë·ªô b·ªÅn c·ªßa t·∫•m nh√¥m m√Ý kh√¥ng l√Ým tƒÉng ƒë·ªô d√Ýy. ƒêi·ªÅu n√Ýy cho ph√©p c√°c v·∫≠t li·ªáu m·ªèng h∆°n ƒë·∫°t ƒë∆∞·ª£c ƒë·ªô c·ª©ng cao h∆°n, khi·∫øn c√°c t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi tr·ªü n√™n l√Ω t∆∞·ªüng cho c√°c h·ªá th·ªëng tr·ªçng l∆∞·ª£ng nh·∫π.

Nh√¥m c√≥ kh·∫£ nƒÉng ch·ªëng oxy h√≥a v√Ý ƒÉn m√≤n t·ª± nhi√™n. Khi k·∫øt h·ª£p v·ªõi k·ªπ thu·∫≠t d·∫≠p n·ªïi, v·∫≠t li·ªáu n√Ýy duy tr√¨ ƒë∆∞·ª£c h√¨nh d·∫°ng v√Ý hi·ªáu nƒÉng ngay c·∫£ khi tr·∫£i qua chu k·ª≥ nhi·ªát l·∫∑p ƒëi l·∫∑p l·∫°i.

Trong c√°c ·ª©ng d·ª•ng c√≥ ƒë·ªô rung li√™n t·ª•c, ch·∫≥ng h·∫°n nh∆∞ xe c·ªô v√Ý m√°y m√≥c, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi mang l·∫°i kh·∫£ nƒÉng ch·ªëng m·ªèi v√Ý c·ªông h∆∞·ªüng t·ªët h∆°n so v·ªõi t·∫•m ph·∫≥ng.

Ng√Ýnh c√¥ng nghi·ªáp √¥ t√¥ l√Ý m·ªôt trong nh·ªØng ng√Ýnh s·ª≠ d·ª•ng nhi·ªÅu t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi nh·∫•t. C√°c khu v·ª±c l·∫Øp ƒë·∫∑t ph·ªï bi·∫øn bao g·ªìm:

ống xả

·ªêng gi·∫£m thanh v√Ý b·ªô chuy·ªÉn ƒë·ªïi x√∫c t√°c

Hệ thống tăng áp

bảo vệ nhiệt dưới thân xe

B·∫±ng c√°ch ph·∫£n x·∫° nhi·ªát ra kh·ªèi c√°c b·ªô ph·∫≠n nh·∫°y c·∫£m, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi gi√∫p c·∫£i thi·ªán ƒë·ªô an to√Ýn, hi·ªáu qu·∫£ v√Ý tu·ªïi th·ªç c·ªßa c√°c linh ki·ªán.

Trong m√¥i tr∆∞·ªùng c√¥ng nghi·ªáp, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi b·∫£o v·ªá c·∫£ thi·∫øt b·ªã v√Ý nh√¢n vi√™n. C√°c ·ª©ng d·ª•ng ƒëi·ªÉn h√¨nh bao g·ªìm:

Hệ thống đường ống nhiệt độ cao

Thiết bị phát điện

L√≤ nung v√Ý bu·ªìng nhi·ªát

Vỏ máy móc gần nguồn nhiệt

C√°c thi·∫øt b·ªã gia d·ª•ng v√Ý th∆∞∆°ng m·∫°i d·ª±a v√Ýo c√°c t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒë·ªÉ duy tr√¨ nhi·ªát ƒë·ªô ho·∫°t ƒë·ªông an to√Ýn trong kh√¥ng gian ch·∫≠t h·∫πp, ƒë·∫∑c bi·ªát l√Ý trong l√≤ n∆∞·ªõng, m√°y s∆∞·ªüi v√Ý c√°c thi·∫øt b·ªã HVAC.

C√°c ki·ªÉu d·∫≠p n·ªïi kh√°c nhau ph·ª•c v·ª• c√°c m·ª•c ƒë√≠ch k·ªπ thu·∫≠t kh√°c nhau. Vi·ªác l·ª±a ch·ªçn ki·ªÉu d·∫≠p n·ªïi ph√π h·ª£p ph·ª• thu·ªôc v√Ýo c√°c y√™u c·∫ßu v·ªÅ nhi·ªát, c∆° h·ªçc v√Ý thi·∫øt k·∫ø.

| Hoa văn dập nổi | Lợi ích chức năng |

|---|---|

| H·ªça ti·∫øt h√¨nh kim c∆∞∆°ng | ƒê·ªô b·ªÅn c√¢n b·∫±ng v√Ý kh·∫£ nƒÉng ph·∫£n x·∫° nhi·ªát |

| M·∫´u s√≥ng | C·∫£i thi·ªán kh·∫£ nƒÉng l∆∞u th√¥ng kh√¥ng kh√≠ v√Ý kh·∫£ nƒÉng ch·ªëng rung. |

| Họa tiết tổ ong | Độ cứng tối đa với trọng lượng tối thiểu |

| Hình học tùy chỉnh | Tối ưu hóa ứng dụng cụ thể |

M·ªói ki·ªÉu hoa vƒÉn ·∫£nh h∆∞·ªüng ƒë·∫øn c√°ch t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi t∆∞∆°ng t√°c v·ªõi nhi·ªát, lu·ªìng kh√¥ng kh√≠ v√Ý ·ª©ng su·∫•t c∆° h·ªçc.

T·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi c√≥ th·ªÉ ƒë∆∞·ª£c ch·∫ø t·∫°o t·ª´ nhi·ªÅu h·ª£p kim nh√¥m kh√°c nhau, t√πy thu·ªôc v√Ýo y√™u c·∫ßu v·ªÅ hi·ªáu su·∫•t.

Nh√¥m 3003: Kh·∫£ nƒÉng t·∫°o h√¨nh v√Ý hi·ªáu su·∫•t nhi·ªát tuy·ªát v·ªùi

Nh√¥m 5052: ƒê·ªô b·ªÅn cao h∆°n v√Ý kh·∫£ nƒÉng ch·ªëng ƒÉn m√≤n t·ªët h∆°n.

Nhôm 8011: Hiệu quả về chi phí cho các ứng dụng khối lượng lớn

0,3 mm ‚Äì Nh·∫π v√Ý linh ho·∫°t

0,6 mm ‚Äì Ti√™u chu·∫©n s·ª≠ d·ª•ng trong c√¥ng nghi·ªáp v√Ý √¥ t√¥

1,0 mm trở lên – Bảo vệ nhiệt chịu tải nặng

Vi·ªác l·ª±a ch·ªçn h·ª£p kim v√Ý ƒë·ªô d√Ýy ph√π h·ª£p ƒë·∫£m b·∫£o t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ho·∫°t ƒë·ªông ƒë√°ng tin c·∫≠y trong ƒëi·ªÅu ki·ªán v·∫≠n h√Ýnh.

Quá trình sản xuất tấm chắn nhiệt bằng nhôm dập nổi bao gồm một số bước được kiểm soát chặt chẽ:

Chu·∫©n b·ªã trang t√≠nh ‚Äì C√°c cu·ªôn ho·∫∑c t·∫•m nh√¥m ƒë∆∞·ª£c l√Ým s·∫°ch v√Ý chu·∫©n b·ªã.

Quy trình dập nổi – Các con lăn chính xác tạo ra các hoa văn nổi đồng đều

C·∫Øt v√Ý t·∫°o h√¨nh ‚Äì Gia c√¥ng c·∫Øt, d·∫≠p ho·∫∑c u·ªën b·∫±ng m√°y CNC t·∫°o h√¨nh cho chi ti·∫øt

Tăng cường bề mặt – Có thể bổ sung thêm các lớp phủ hoặc lớp phản quang tùy chọn.

Ki·ªÉm tra v√Ý th·ª≠ nghi·ªám ‚Äì Ki·ªÉm tra ch·∫•t l∆∞·ª£ng v·ªÅ k√≠ch th∆∞·ªõc v√Ý h√¨nh th·ª©c

Quy tr√¨nh n√Ýy ƒë·∫£m b·∫£o t√≠nh nh·∫•t qu√°n, ƒë·ªô ch√≠nh x√°c v·ªÅ hi·ªáu su·∫•t v√Ý kh·∫£ nƒÉng m·ªü r·ªông cho s·∫£n xu·∫•t h√Ýng lo·∫°t.

Tấm chắn nhiệt bằng nhôm dập nổi được thiết kế tốt mang lại khả năng bảo vệ nhiệt ổn định trong phạm vi nhiệt độ rộng.

Phản xạ một tỷ lệ nhiệt bức xạ cao.

Duy tr√¨ ƒë·ªô ·ªïn ƒë·ªãnh ngay c·∫£ khi l√Ým n√≥ng v√Ý l√Ým l·∫°nh nhi·ªÅu l·∫ßn.

Ch·ªëng n·ª©t, cong v√™nh v√Ý h∆∞ h·ªèng b·ªÅ m·∫∑t.

Trong nhi·ªÅu ·ª©ng d·ª•ng, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ho·∫°t ƒë·ªông hi·ªáu qu·∫£ ·ªü nhi·ªát ƒë·ªô l√™n ƒë·∫øn 500‚Äì600¬∞C, t√πy thu·ªôc v√Ýo lo·∫°i h·ª£p kim v√Ý ph∆∞∆°ng ph√°p l·∫Øp ƒë·∫∑t.

Các sản phẩm tiêu chuẩn có thể không luôn đáp ứng được các yêu cầu cụ thể của dự án. Giải pháp tấm chắn nhiệt bằng nhôm dập nổi tùy chỉnh cho phép các kỹ sư tối ưu hóa hiệu suất cho các điều kiện đặc thù.

Các mẫu dập nổi được thiết kế riêng

Cấu trúc nhiều lớp

Vật liệu cách nhiệt tích hợp

H√¨nh d·∫°ng ph·ª©c t·∫°p v√Ý c√°c ƒë·∫∑c ƒëi·ªÉm l·∫Øp ƒë·∫∑t

C√°c thi·∫øt k·∫ø t√πy ch·ªânh ƒë·∫∑c bi·ªát c√≥ gi√° tr·ªã ƒë·ªëi v·ªõi c√°c nh√Ý s·∫£n xu·∫•t thi·∫øt b·ªã g·ªëc (OEM) v√Ý c√°c nh√Ý t√≠ch h·ª£p h·ªá th·ªëng ƒëang t√¨m ki·∫øm hi·ªáu qu·∫£ t·∫£n nhi·ªát t·ªët h∆°n v√Ý b·ªë c·ª•c nh·ªè g·ªçn h∆°n.

Khi lựa chọn tấm chắn nhiệt bằng nhôm dập nổi, hãy cân nhắc các yếu tố sau:

Hi·ªÉu r√µ ph·∫°m vi nhi·ªát ƒë·ªô, h∆∞·ªõng nhi·ªát v√Ý th·ªùi gian ti·∫øp x√∫c.

C·∫ßn t√≠nh ƒë·∫øn ƒë·ªô rung, ƒë·ªô ·∫©m, h√≥a ch·∫•t v√Ý c√°c h·∫°n ch·∫ø v·ªÅ kh√¥ng gian.

Ng√Ýnh c√¥ng nghi·ªáp √¥ t√¥ v√Ý c√¥ng nghi·ªáp n√≥i chung th∆∞·ªùng y√™u c·∫ßu tu√¢n th·ªß c√°c ti√™u chu·∫©n c·ª• th·ªÉ.

M·ªôt nh√Ý cung c·∫•p ƒë√°ng tin c·∫≠y c·∫ßn c√≥ chuy√™n m√¥n v·ªÅ v·∫≠t li·ªáu, ki·ªÉm so√°t ch·∫•t l∆∞·ª£ng nh·∫•t qu√°n v√Ý h·ªó tr·ª£ t√πy ch·ªânh s·∫£n ph·∫©m.

C√¥ng ngh·ªá d·∫≠p n·ªïi gi√∫p c·∫£i thi·ªán ƒë·ªô c·ª©ng, gi·∫£m truy·ªÅn nhi·ªát v√Ý tƒÉng kh·∫£ nƒÉng ch·ªëng rung m√Ý kh√¥ng l√Ým tƒÉng tr·ªçng l∆∞·ª£ng.

Trong nhi·ªÅu ·ª©ng d·ª•ng, c√¢u tr·∫£ l·ªùi l√Ý c√≥. ƒê·ªô b·ªÅn c·ªßa nh√¥m cho ph√©p s·ª≠ d·ª•ng l√¢u d√Ýi n·∫øu kh√¥ng b·ªã h∆∞ h·∫°i v·ªÅ m·∫∑t v·∫≠t l√Ω.

Đúng vậy. Thiết kế nhiều lớp với lớp cách nhiệt phía sau rất phổ biến trong môi trường có nhiệt độ cực cao.

ƒê√∫ng v·∫≠y. Kh·∫£ nƒÉng ch·ªëng ƒÉn m√≤n c·ªßa nh√¥m khi·∫øn ch√∫ng ph√π h·ª£p v·ªõi ƒëi·ªÅu ki·ªán ngo√Ýi tr·ªùi v√Ý kh·∫Øc nghi·ªát.

ƒê·ªô d√Ýy ph·ª• thu·ªôc v√Ýo nhi·ªát ƒë·ªô ti·∫øp x√∫c, ·ª©ng su·∫•t c∆° h·ªçc v√Ý gi·ªõi h·∫°n tr·ªçng l∆∞·ª£ng.

Ch·∫Øc ch·∫Øn r·ªìi. K·ªπ thu·∫≠t d·∫≠p n·ªïi r·∫•t ph√π h·ª£p cho c·∫£ s·∫£n xu·∫•t s·ªë l∆∞·ª£ng nh·ªè v√Ý s·∫£n xu·∫•t h√Ýng lo·∫°t.

M·ªòT t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒê√¢y l√Ý gi·∫£i ph√°p ƒë√£ ƒë∆∞·ª£c ch·ª©ng minh hi·ªáu qu·∫£ trong vi·ªác qu·∫£n l√Ω nhi·ªát trong c√°c ·ª©ng d·ª•ng √¥ t√¥, c√¥ng nghi·ªáp v√Ý th∆∞∆°ng m·∫°i. S·ª± k·∫øt h·ª£p gi·ªØa hi·ªáu su·∫•t nhi·ªát, ƒë·ªô b·ªÅn nh·∫π v√Ý t√≠nh linh ho·∫°t trong thi·∫øt k·∫ø khi·∫øn n√≥ tr·ªü th√Ýnh l·ª±a ch·ªçn tuy·ªát v·ªùi cho nh·ªØng th√°ch th·ª©c qu·∫£n l√Ω nhi·ªát hi·ªán ƒë·∫°i.

B·∫±ng c√°ch l·ª±a ch·ªçn v·∫≠t li·ªáu, ki·ªÉu d·∫≠p n·ªïi v√Ý nh√Ý cung c·∫•p ph√π h·ª£p, c√°c doanh nghi·ªáp c√≥ th·ªÉ ƒë·∫°t ƒë∆∞·ª£c kh·∫£ nƒÉng b·∫£o v·ªá nhi·ªát ƒë√°ng tin c·∫≠y ƒë·ªìng th·ªùi t·ªëi ∆∞u h√≥a hi·ªáu su·∫•t v√Ý chi ph√≠. Cho d√π l√Ý ti√™u chu·∫©n hay thi·∫øt k·∫ø ri√™ng, t·∫•m ch·∫Øn nhi·ªát b·∫±ng nh√¥m d·∫≠p n·ªïi ƒë√≥ng vai tr√≤ quan tr·ªçng trong vi·ªác c·∫£i thi·ªán an to√Ýn, hi·ªáu qu·∫£ v√Ý tu·ªïi th·ªç s·∫£n ph·∫©m.