Khi lựa chọn vật liệu cách nhiệt khí thải Lựa chọn đúng đắn hiếm khi chỉ dựa trên những lời quảng cáo tiếp thị — mà là dựa trên... nhiệt độ hoạt động, môi trường và độ tin cậy lâu dài Trong các hệ thống ống xả thực tế, các vật liệu khác nhau sẽ có phản ứng rất khác nhau khi tiếp xúc liên tục với nhiệt độ cao, độ rung và các chu kỳ bảo trì.

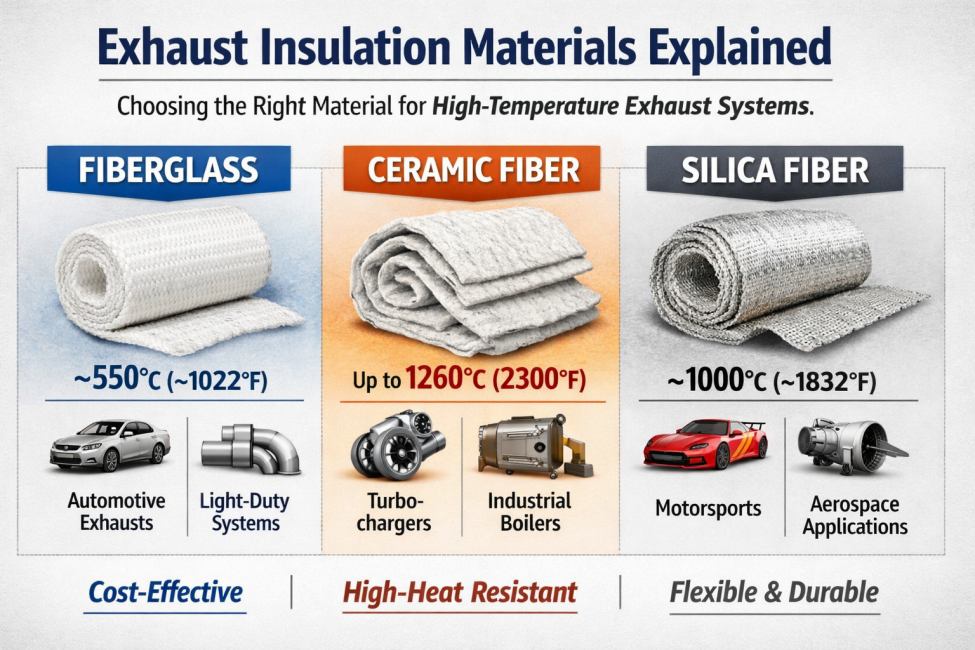

Bài viết này giải thích cách thức vật liệu cách nhiệt sợi thủy tinh, sợi gốm và silica Thực tế, mỗi loại vật liệu sẽ phát huy tác dụng trong các ứng dụng khí thải, và mỗi loại thì không.

Các bộ phận của hệ thống xả thường hoạt động trong điều kiện ứng suất nhiệt liên tục Không chỉ là những đợt tăng nhiệt ngắn hạn. Trên thực tế, nhiều sự cố hỏng hóc vật liệu cách nhiệt xảy ra không phải vì nhiệt độ định mức bị vượt quá một lần, mà là do... vật liệu bị xuống cấp theo thời gian .

Việc lựa chọn vật liệu không phù hợp có thể dẫn đến:

Sự suy giảm dần hiệu quả cách nhiệt

Sự đứt gãy sợi dưới tác động rung động

Nhiệt độ bề mặt tăng lên

Tuổi thọ sử dụng ngắn và cần thay thế thường xuyên.

Vì lý do này, các kỹ sư giàu kinh nghiệm thường lựa chọn vật liệu cách nhiệt ống xả dựa trên các yếu tố sau: nhiệt độ hoạt động liên tục Không chỉ dựa vào xếp hạng cao nhất.

Trong các ứng dụng ống xả thực tế, vật liệu cách nhiệt phải đáp ứng một số yêu cầu không thể thiếu:

Hiệu suất ổn định dưới nhiệt độ cao liên tục

Khả năng chống rung cơ học

Độ dẫn nhiệt thấp theo thời gian

Khả năng tương thích với dầu, độ ẩm và hóa chất

Thành phần không độc hại, không chứa amiăng

Các vật liệu hoạt động tốt trong điều kiện phòng thí nghiệm vẫn có thể bị hỏng sớm nếu bỏ qua các yếu tố này.

Sợi thủy tinh được sử dụng rộng rãi trong vật liệu cách nhiệt ống xả do tính sẵn có và hiệu quả về chi phí. Tuy nhiên, nó thường được lựa chọn. với những hạn chế được hiểu rõ. .

Nhiệt độ duy trì: lên đến ~500–550°C

Tiếp xúc ngắn hạn ở nhiệt độ cao hơn mức này có thể đẩy nhanh quá trình xuống cấp.

Hệ thống hút khí công nghiệp nhẹ

Ống xả ô tô đặt cách xa bộ tăng áp.

Các ứng dụng ưu tiên kiểm soát chi phí

Tiếp xúc liên tục ở nhiệt độ trên 600°C

Bộ tăng áp hoặc hệ thống xả công nghiệp tải trọng cao

Môi trường bị ô nhiễm dầu nặng

Trên thực tế, sợi thủy tinh thường được sử dụng làm vật liệu. vật liệu cách nhiệt cơ bản nhưng không thích hợp cho các ứng dụng nhiệt độ cực cao.

Sợi gốm thường được lựa chọn khi nhiệt độ khí thải cao. luôn ở mức cao và tính ổn định nhiệt lâu dài là rất quan trọng.

Nhiệt độ duy trì: lên đến ~1260°C

Duy trì khả năng cách nhiệt ngay cả trong điều kiện nhiệt độ cao kéo dài.

Độ dẫn nhiệt rất thấp

Thích hợp cho các thiết kế cách nhiệt nhỏ gọn.

Bộ tăng áp và ống xả

Lò công nghiệp và nồi hơi

Hệ thống xả khí thải máy phát điện

Trong các dự án công nghiệp thực tế, sợi gốm thường được lựa chọn khi nhiệt độ khí thải thường xuyên vượt quá 800°C , nơi mà các vật liệu khác bắt đầu mất hiệu quả.

Vật liệu cách nhiệt sợi silica thường được lựa chọn cho các ứng dụng yêu cầu sự kết hợp của các yếu tố sau: khả năng chịu nhiệt cao và tính linh hoạt .

Nhiệt độ duy trì: lên đến ~1000°C

Khả năng chịu sốc nhiệt tuyệt vời

Hoạt động tốt trong điều kiện rung động.

Vẫn giữ được độ dẻo dai sau nhiều chu kỳ gia nhiệt.

Hệ thống ống xả dành cho xe đua và hiệu suất cao

Các thành phần liên quan đến turbo

Ứng dụng với chu kỳ nhiệt thường xuyên

Sợi silica thường được sử dụng khi khả năng chịu lực và chuyển động cơ học cũng quan trọng như khả năng chịu nhiệt.

Lớp lõi cách nhiệt thôi hiếm khi đủ trong môi trường khí thải. Các lớp bảo vệ bên ngoài rất quan trọng đối với độ bền.

Lưới thép không gỉ có khả năng chống mài mòn

Sợi thủy tinh phủ silicone giúp chống ẩm và dầu.

Vải được xử lý bằng PTFE để kháng hóa chất

Mặc dù các lớp ngoài không cung cấp khả năng cách nhiệt chính, nhưng chúng kéo dài đáng kể tuổi thọ sử dụng và nâng cao độ an toàn trong điều kiện vận hành thực tế.

| Vật liệu | Nhiệt độ liên tục | Tính linh hoạt | Tuổi thọ sử dụng điển hình | Trường hợp sử dụng tốt nhất |

|---|---|---|---|---|

| Sợi thủy tinh | ~550°C | Cao | Ngắn-Trung bình | Ống xả hạng nhẹ |

| Sợi gốm | ~1260°C | Trung bình | Dài | Nhiệt độ cực cao |

| Sợi silica | ~1000°C | Rất cao | Trung bình-Dài | Rung động cao |

Sự so sánh này phản ánh hiệu suất thực địa điển hình Không chỉ là dữ liệu thí nghiệm.

Trong nhiều ứng dụng hiệu năng cao, vật liệu cách nhiệt được kết hợp thành nhiều thành phần khác nhau. hệ thống chăn cách nhiệt ống xả nhiều lớp Cách tiếp cận này cho phép các nhà sản xuất:

Tối ưu hóa hiệu suất nhiệt

Cân bằng giữa tính linh hoạt và độ bền.

Đảm bảo tính năng vật liệu phù hợp với điều kiện vận hành.

Việc lựa chọn vật liệu trong các hệ thống này được thúc đẩy bởi... chức năng Không phải vẻ bề ngoài.

Trên thực tế, việc tuyển chọn thường xoay quanh ba câu hỏi:

Nhiệt độ hoạt động liên tục là bao nhiêu?

Mức độ rung động hoặc chuyển động như thế nào?

Có những tác động môi trường nào (dầu, hơi ẩm, hóa chất)?

Đối với các hệ thống phức tạp hoặc có nhiệt độ cao, tấm cách nhiệt ống xả tùy chỉnh Việc sử dụng sự kết hợp vật liệu phù hợp thường là giải pháp lâu dài đáng tin cậy nhất.

Việc lựa chọn vật liệu phù hợp—hoặc sự kết hợp các vật liệu—giúp giảm nhiệt độ bề mặt, cải thiện hiệu suất và kéo dài tuổi thọ thiết bị. Đối với các ứng dụng đòi hỏi cao, cần có thiết kế chuyên nghiệp. hệ thống chăn cách nhiệt khí thải Cung cấp kết quả nhất quán và đáng tin cậy nhất.