Khi nói đến hệ thống ống xả cách điện, một Ống xả tay áo● Còn được gọi là Tay áo ống xả, ống xả bị tụt lại hoặc máy sưởi diesel bị trễ● rất cần thiết để giảm mất nhiệt, tăng cường hiệu suất và đảm bảo an toàn Được thiết kế để chịu được nhiệt độ khắc nghiệt, những tay áo này được chế tạo từ các vật liệu hiệu suất cao, mỗi loại cung cấp những lợi thế độc đáo phù hợp với các ứng dụng cụ thể

Điện trở nhiệt độ: Lên đến 1000â ° F (540â ° C) liên tục, 1200â ° F (650 ° C) không liên tục

Đặc trưng: Hiệu quả về chi phí, linh hoạt và dễ cài đặt

Tốt nhất cho: General Ô tô, Hàng hải, và cách nhiệt công nghiệp

Ví dụ ứng dụng: Được sử dụng trong ống xả ô tô và máy móc công nghiệp để giảm truyền nhiệt và ngăn ngừa bỏng trong không gian hạn chế

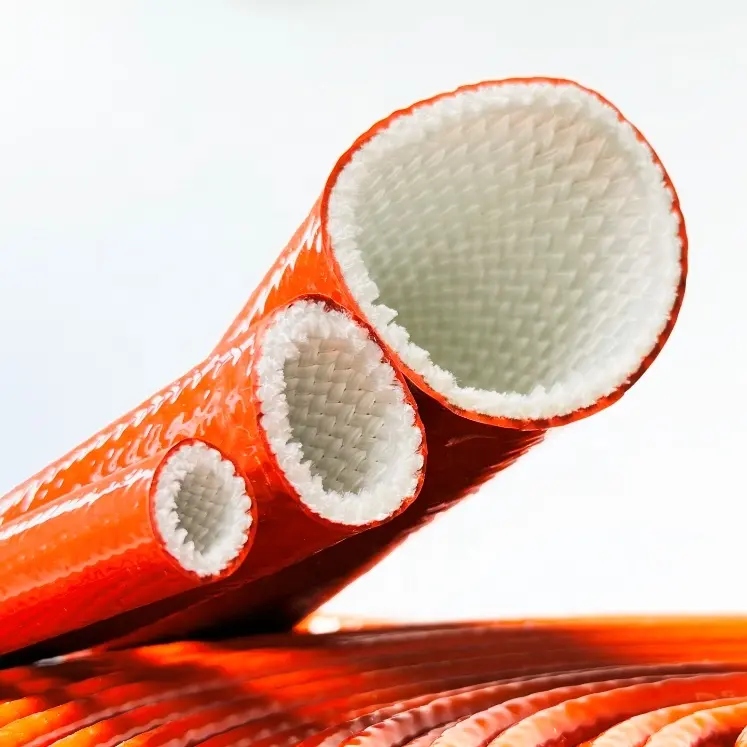

Điện trở nhiệt độ: Lõi sợi thủy tinh lên đến 1000â ° F (540â ° C), lớp phủ silicon lên tới 500â ° F (260â ° C)

Đặc trưng: Chống nước, kháng dầu và bền chống mài mòn

Tốt nhất cho: Các bộ phận xả ngoài trời và tiếp xúc, máy sưởi diesel và các ứng dụng biển

Ví dụ ứng dụng: Được lắp đặt trên các ống xả nóng diesel trong các phương tiện off-road để ngăn chặn thiệt hại nhiệt cho các thành phần gần đó trong khi cung cấp độ ẩm và khả năng chống dầu

Điện trở nhiệt độ: Lên đến 1382â ° F (750â ° C) liên tục, 1832â ° F (1000â ° C) không liên tục

Đặc trưng: Cách nhiệt vượt trội, khả năng chống cháy tự nhiên và độ bền tuyệt vời

Tốt nhất cho: Các ứng dụng công nghiệp ô tô, hàng không vũ trụ và công nghiệp hạng nặng

Ví dụ ứng dụng: Được sử dụng trong các phương tiện đua xe và hiệu suất để bọc các ống xả turbo, giảm nhiệt độ dưới chân và tăng cường hiệu quả

Điện trở nhiệt độ: Lên đến 1800â ° F (982â ° C) liên tục, 3000â ° F (1650 ° C) không liên tục

Đặc trưng: Khả năng chống nhiệt cực độ, không đốt cháy và có độ bền cao

Tốt nhất cho: Không gian vũ trụ, môi trường công nghiệp cực đoan và các ứng dụng đua hiệu suất cao

Ví dụ ứng dụng: Áp dụng trong cách nhiệt của khí thải động cơ máy bay để quản lý khí thải nhiệt độ cao một cách an toàn trong khi giảm thiểu nhiệt ngâm trong các khu vực nhạy cảm

Hiệu suất nhiệt: Giảm bức xạ nhiệt và cải thiện hiệu suất hệ thống

Bảo vệ nhân sự: Giảm thiểu nguy cơ bỏng và thương tích trong khu vực bảo trì

Độ bền nâng cao: Bảo vệ các thành phần xả khỏi suy thoái nhiệt, kéo dài tuổi thọ dịch vụ

Các ứng dụng đa năng: Thích hợp cho sử dụng ô tô, biển, công nghiệp và hàng không vũ trụ

Để có hiệu suất tốt nhất và tuổi thọ, chọn quyền Ống xả tay áo Phụ thuộc vào các yêu cầu nhiệt độ cụ thể và điều kiện môi trường của ứng dụng của bạn Cho dù bạn cần sợi thủy tinh cho hiệu quả chi phí, sợi thủy tinh phủ silicon để có độ bền, sợi bazan cho khả năng phục hồi nhiệt độ cao hoặc sợi silica cho điều kiện nhiệt cực độ, có một giải pháp hoàn hảo để đáp ứng nhu cầu cách nhiệt của bạn.